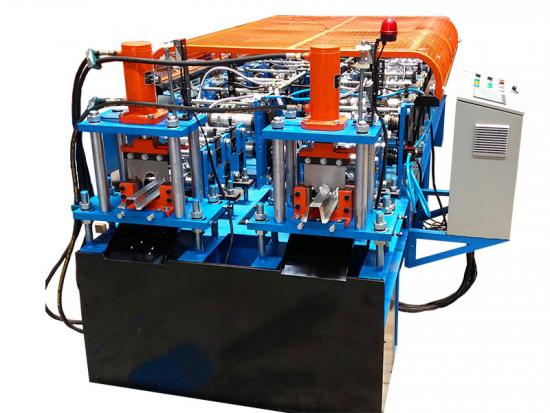

Top Hat Pulin Roll Forming Machine

PAYMENT:T/T,L/C,CASH

LEAD TIME:2~3Months

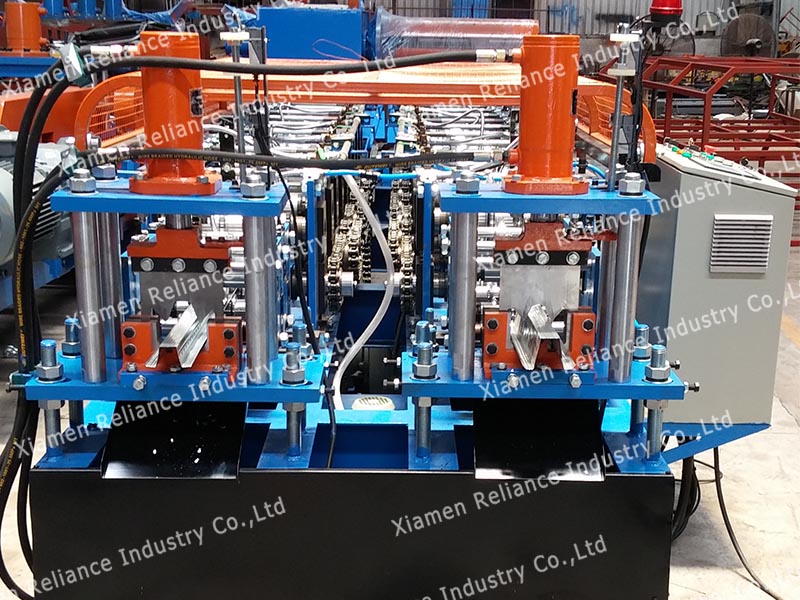

WAY OF PACKAGING:Nude place in container, machine body tightened with steel wire rope and base frame position fixed by heavy steel angle plate. Roller groups cover with waterproof cloth. Computer control system packed with plywood box. Tooling box and regular wearing parts packed with plywood box as well.

ADVANTAGE FEATURES:1.De-coiler storage steel coils and smoothly feeding into forming machine labor save operation. 2. Forming, Punching & cutting at any required length with pre-set quantity automatically. 3.The encoder will record signal feedback and showing exact length of product on display. 4.The total length of finished coil is able to calculate via control panel. 5.Steel rollers are fabricated by CNC precision machine and hard chrome coated. 6.Cutting blade material is Cr12/Cr12Mov (D2/D3) fabricated by CNC machine, heat treatment. 7. Hydraulic system will equip cooling system to keep low temperature during long time continuously in one day.

▶Ceiling Top Hat Roll Forming Machine/Top Hat roll forming machine/Steel Stud forming machine

This dual side furring channel roll forming machine can produce two different shape top hats on one machine that save space and more economical

The hat section can be fabricated from various material thicknesses and in almost any length. With highly dimension forming automatically and cut to length, the forming line capable well improved customer production capacity. In line punching and rib strengthening are also available as per customer particular requirements.

▶The production line system includes:

Decoiler/Uncoiler

Dual material feed

Forming machine with water cooling system

Blow dry DEVICE

Automatic cutting section

Electrical control system

Product run out table

▶Ceiling channel roll forming:

▶Top hat roll forming:

▶Ceiling top hat section machine:

▶Ceiling section:

CZ & Sigma Purlin Machine

CZ & Sigma Purlin Machine