Auto CU60-200 Purlin Machine post cutting

Description

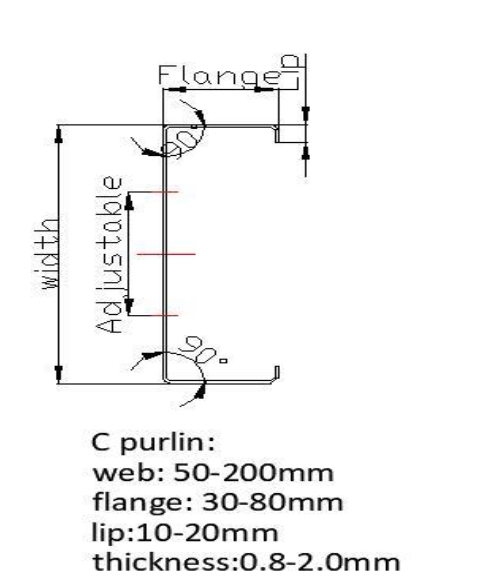

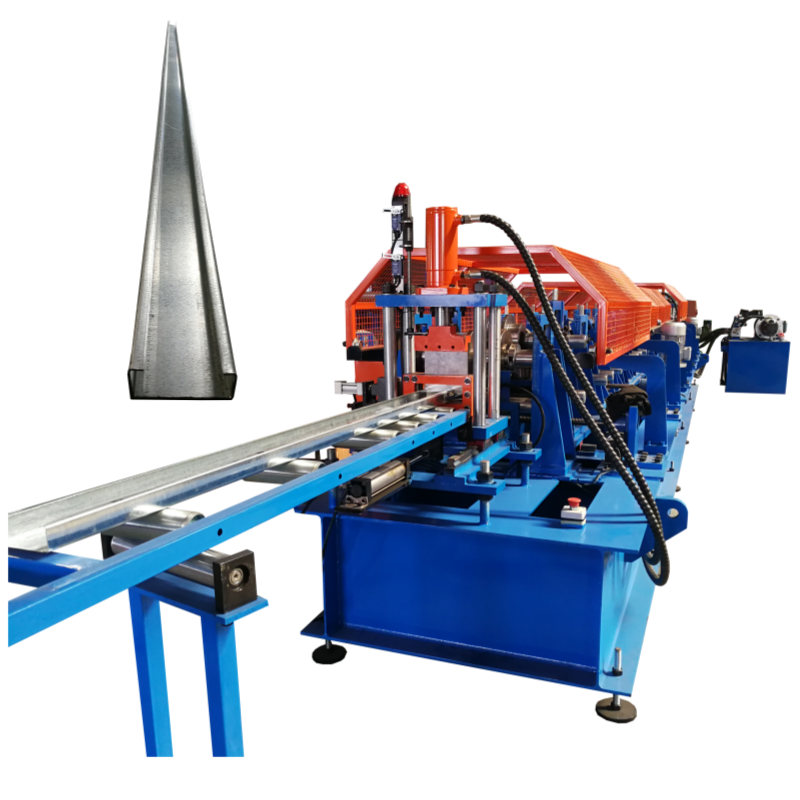

C50-200 Channel Machine/quick change C50-200 purlin roll forming machine/adaptable C50-200 c purlin machine/C50-200 auto c purlin machine is use to produce small size range C purlins. Size range variable from 50-200mm. Thickness range from 0.8~2.0mm.

This machine is widely used in PEB construction field. Its size range can be made as per desired requirements and can be fabricated from various material thicknesses and in almost any length. With highly punching accuracy, accurate dimension forming automatically and cut to length, the forming line capable well improved customer production capacity.

Reliance offer on-site installation, training and maintenance if have demand.

Working Procedure:

Uncoiling– Leveling– Servo Feeding and Punching– Pre-notching– Roll Forming Machine–Post cutting– Collecting

Technical Details

Available produced C purlin sizes:

Machine Specifications | |

Weight | 9800KGS |

Sizes | 11.5*1.8*1.6M |

Color | Main machine color: Blue |

Mesh cover: Orange | |

Suitable Raw Material | |

Material | Galvanized /HR/CR Mild Steel |

Thickness | 0.8~2.0mm |

Coil width | 125-390MM |

Yield strength | 250-550Mpa |

Main Technical Parameters | |

Forming roller station quantity | 14 stations |

Material of rollers | GCr15 steel with quenched treatment |

Diameter of shafts | ф45mm |

Material of shafts | 45﹟ casting steel |

Line forming speed | 20m/min |

Punching die material | Cr12 mould steel with quenched treatment |

Cutting die material | Cr12 mould steel with quenched treatment |

Control system | PLC(Siemens), Touch Screen(Siemens), Inverter (Schneider), Encoder(Omron) |

Line power requirement | Main driven motor: 15KW |

Size changing motor: 1*1.5KW, 2*0.75KW | |

Hydraulic Pack motor: 11KW | |

Electric voltage standard | As per customer requirements |

Main Components:

3Ton Uncoiler Rack

Manual expanding mandrel and motor driven rotation

Work coil width: max 600mm

Pre-leveling & Pre-punching & Pre-cutting & Pre-notching Device

The section firstly making the strip material flat before feeding into roll forming machine

Then punching and notching process before going into roll forming process

The pre-cutting device only use during exchange coil strips

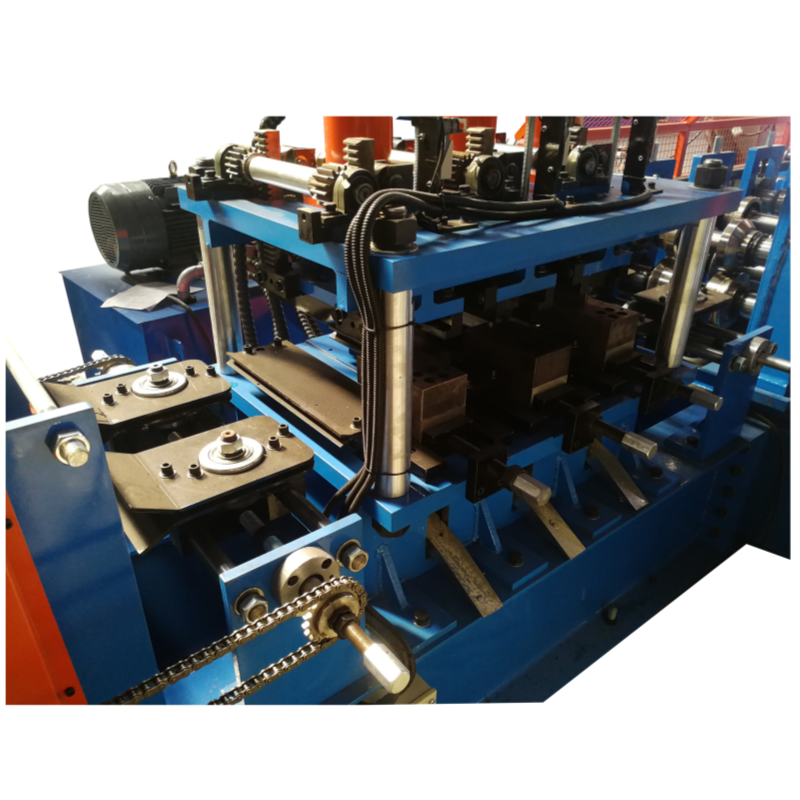

Main roll forming machine

Driven type: gear sprocket with chain connection

Standard stand frame design with full mesh cover around main forming machine

Hydraulic no-stop-cutting section

Post cutting for all c purlin profiles, all sizes sharing one cutting blade

Save time and high efficiency

PLC control cabinet

All international brand elements composited and qualified system

With portable controller for convenient work usage

Production run out table

Handel forming sheets for packing

CZ & Sigma Purlin Machine

CZ & Sigma Purlin Machine